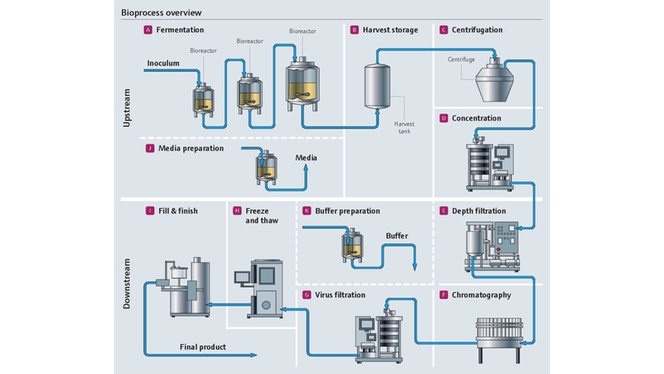

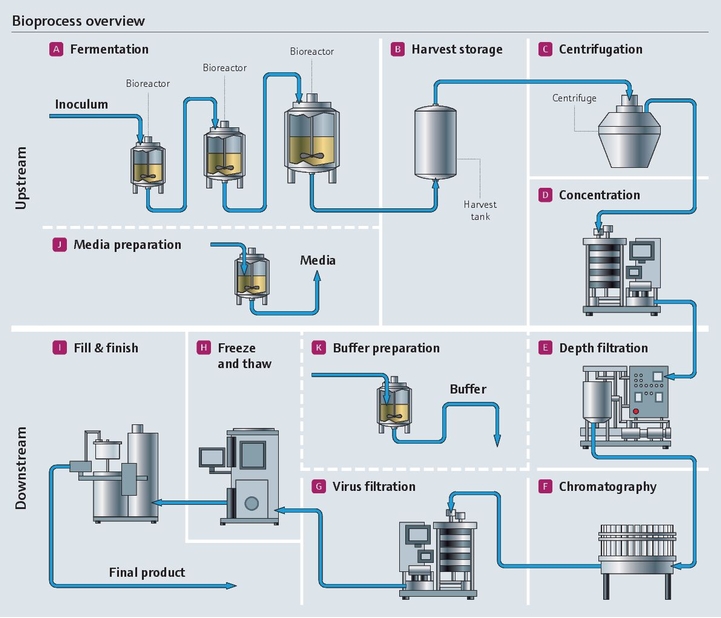

소규모 프로세스 개발에서 GMP 의약품 제조로의 전환은 쉽지 않습니다. 더 높은 수준의 자동화와 제어, 새로운 계기와 기술로 인해 복잡성이 증가합니다. 또한 GMP 규정, 산업 표준, 가이드라인 등 품질 규격 충족을 위한 모든 사항을 준수해야 합니다. 엔드레스하우저의 의약품 제조 포트폴리오는 품질 및 프로세스 파라미터의 실시간 모니터링과 제어를 통해 생산성 목표 달성을 지원합니다.

핵심 정보

100%

matching instruments

to user requirements - perfectly engineered, right first time

계측 기기의 표준화

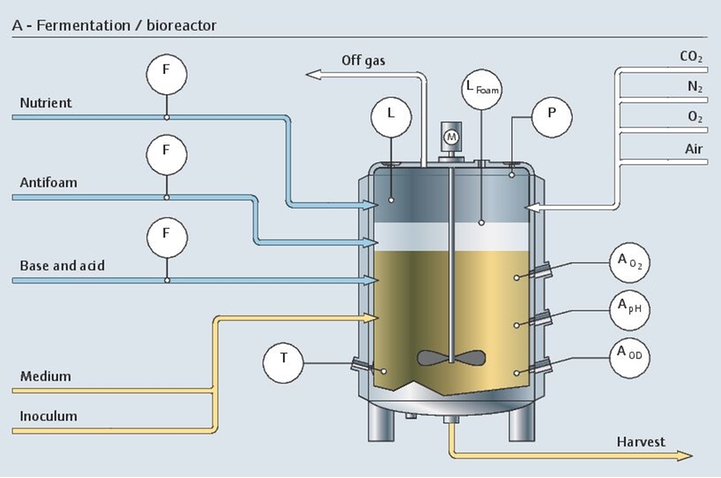

발효 프로세스의 제어

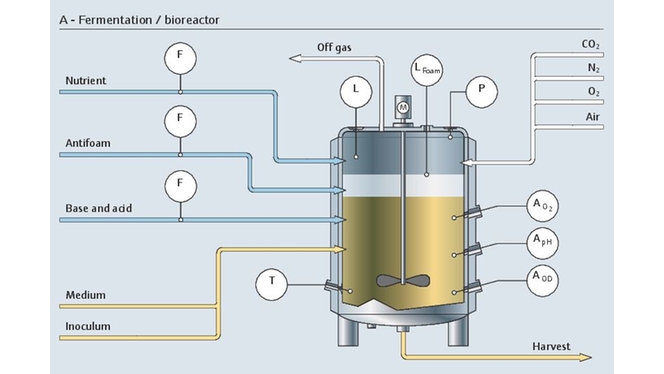

살아 있는 세포를 이용하는 발효는 매우 복잡하고 민감하며 비용 집약적인 바이오프로세스입니다. 바이오의약품 제조 프로세스 전체에 걸쳐 무균 조건이 엄격하게 지켜져야 하며, 이러한 요건을 충족하려면 일관된 측정이 매우 중요합니다.

분야별 전문성

장기적인 안정성과 정확성을 보장하는 엔드레스하우저의 계기 포트폴리오는 바이오리액터 조건의 완전한 제어를 보장합니다.

- 이중 pH 및 광학 밀도 측정

- 일관된 온도 제어, 최적화된 헤드 스페이스 및 거품 레벨 보장

- 공급 유량 및 압력 제어 모니터링

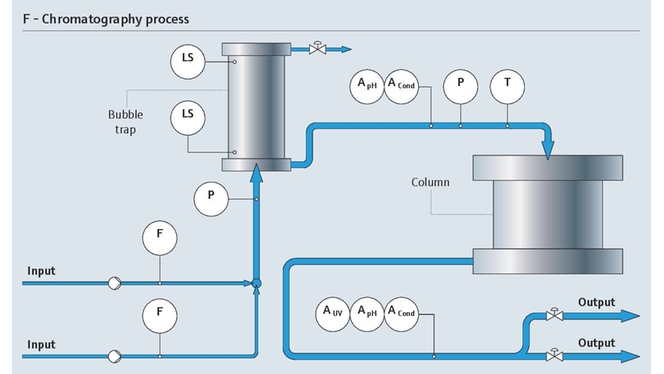

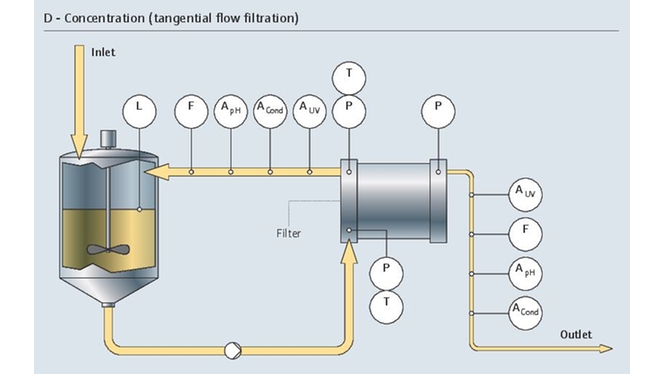

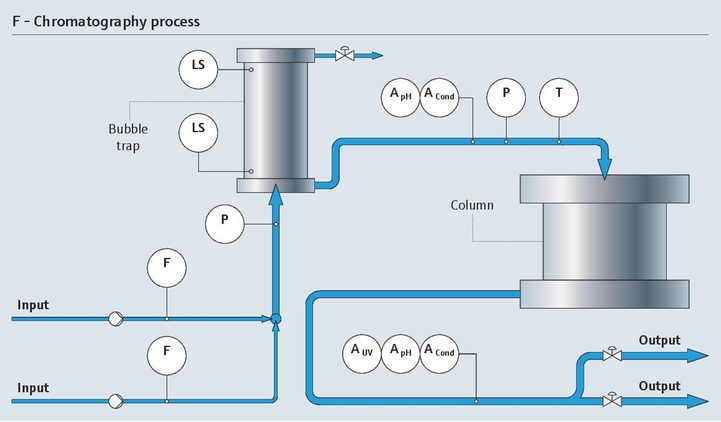

효율적인 크로마토그래피

크로마토그래피를 수행할 경우 전도도와 pH 파라미터의 정확한 측정이 필수입니다. 또한 복잡한 발효액 혼합물에서 분리할 목표 단백질을 찾는 것은 쉽지 않은 과제입니다.

분야별 전문성

엔드레스하우저의 모니터링 솔루션은 필수적인 크로마토그래피 조건을 유지해 분리 프로세스를 지원합니다. 또한 목표 단백질을 쉽게 찾을 수 있도록 UV 프로세스 광도계 센서를 제공합니다.

- pH 및 전도도 측정 최적화

- 유량 제어 최적화

- 과압 및 과열로부터 프로세스 보호

안정적인 pH 측정

pH는 바이오리액터에서 중요한 제어 파라미터 중 하나입니다. 각 세포주는 효율적인 세포 성장과 단백질 발현에 최적화된 pH 범위를 갖습니다. 실험실에서 대량 생산에 이르기까지 일관되고 신뢰할 수 있는 데이터는 필수입니다.

분야별 전문성

엔드레스하우저의 포트폴리오는 모든 규모에서 신뢰성을 극대화하기 위해 발효 중에 안정적인 인라인 pH 측정을 보장하고 실험실에는 혁신적인 교정 시스템을 구현합니다.

- Memosens 최첨단 센서 기술 이용

- 실험실에서 대규모 제조에 이르기까지 동일한 디지털 기술을 센서와 계기에 구현

장점

클라우스 쾰러(Klaus Kohler)와 같은 엔드레스하우저의 전문가와 함께 바이오의약품 제조 프로세스 프로젝트를 간소화해 보시기 바랍니다. 이들은 계측 기기와 관련 산업에 대한 풍부한 지식과 전문성을 바탕으로 고객의 요건에 부합하는 최상의 솔루션을 찾아줍니다.

핵심 정보

80 %

계측 기기 유형의 다양성 감소

핵심 정보

2 개월

시장 출시 시간 단축

핵심 정보

0

처음부터 올바른 사양을 선택한 덕분에 계기 변경 불필요

엔드레스하우저의 지원 방식

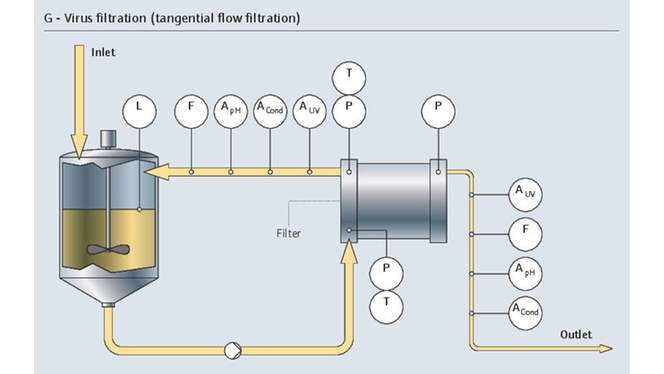

엔드레스하우저는 의약품 제조 우수성을 보장하는 완전한 확장형 솔루션 포트폴리오를 제공합니다. 엔드레스하우저의 계기와 센서는 중요한 프로세스 조건을 정확하게 모니터링하여 규정 준수와 배치 출하를 보장합니다.

- 바이오리액터 및 거품 레벨 측정 및 제어

- 크로마토그래피 스키드에서 단백질 분리

- 실험실 및 제조 프로세스의 분석 측정

- 교정이 간편한 현장 계측 기기

- 모든 계측 기기가 ASME BPE 표준에 따라 설계