Temperature monitoring for gasifiers

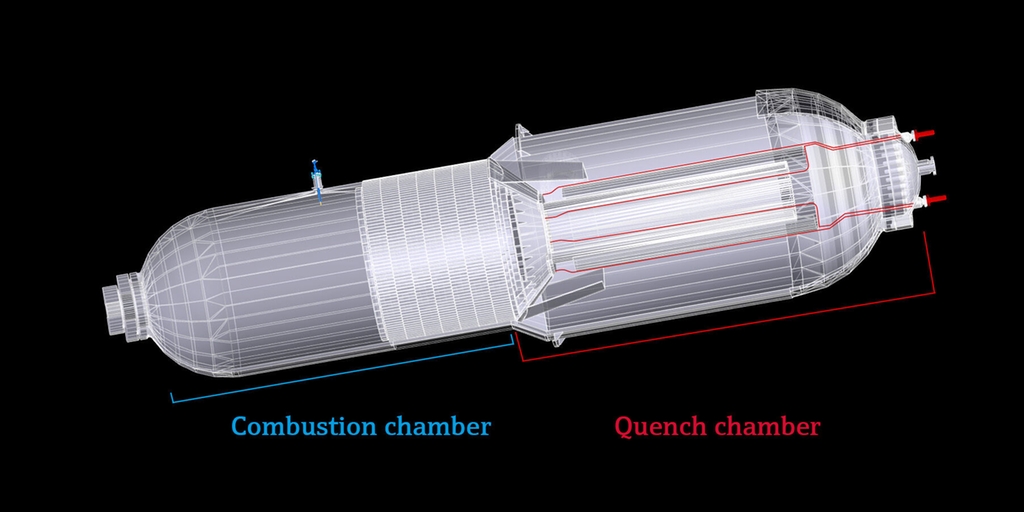

Measurement inside the combustion chamber and quench chamber

High-temperature reactors (gasifiers) are used to produce syngas by steam reforming or partial oxidation of liquid hydrocarbons, natural gas, or coal in their plant. This application is also known as integrated gasification combined cycle (IGCC). The extreme and harsh operating conditions that exist within the gasifier contribute to the difficulty of accurate temperature measurement with this setting.

Benefits

Process optimization: Accurate temperature measurements in the combustion chamber allow optimized preheating of the feedstocks and uniform thermal behavior when reacting at the desired temperature.

Reliability: Monitoring of the operating temperature of the internal refractory layers which are progressively consumed by possible hot process zones.

Safety: Leak detection through the diagnostic chamber feature increases the level of safety, allowing the instrument to operate even with hydrogen diffusion through the wetted components.

Performance monitoring & maintenance: Accurate and very local temperature measurements allow thermal-gradient calculation through specific gasifier’s zones along the quench ring (e.g. through the passage between the combustion and quench chamber).

Environmental compliance: Dual seal protection and leak detection capabilities ensure the gasifier stays in compliance regarding emissions of toxic fluids and extends the life of the refractory materials that otherwise shall be replaced.

The challenge

Harsh operating conditions: Extremely high temperatures with more than 1200 °C (2192 °F) in some areas and high pressure combustion at 45 bar.

Corrosive atmosphere: Presence of gases like hydrogen sulfide that can decrease the performance and lifespan of temperature sensors.

Limited access and mounting options: Only limited entry points into the enclosed system of a gasifier and reactor walls under high pressure.

Our solution

To address the challenges, specialized temperature measurement techniques and sensors, designed to withstand high temperatures and harsh environments, were developed by Endress+Hauser. Those so-called Temperature Engineered Solutions (TES) are based on standard products, adapted to specific customer requirements. Both assemblies (TAF16, iTHERM MultiSens TMS02) are highly modular for easy maintenance through spares planning and include replaceable sensor inserts.

| FLEX 선택 | 기술적 우수성 | 단순성 |

|---|---|---|

Fundamental 선택 기본적인 측정 요구사항 충족 |

기술적 우수성

|

단순성

|

Lean 선택 핵심 프로세스를 손쉽게 처리 |

기술적 우수성

|

단순성

|

Extended 선택 혁신적인 기술로 프로세스 최적화 |

기술적 우수성

|

단순성

|

Xpert 선택 가장 까다로운 어플리케이션 요구사항 충족 |

기술적 우수성

|

단순성

구성에 따라 다름 |