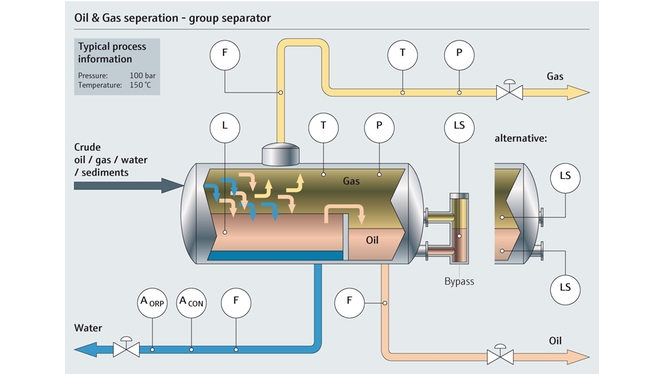

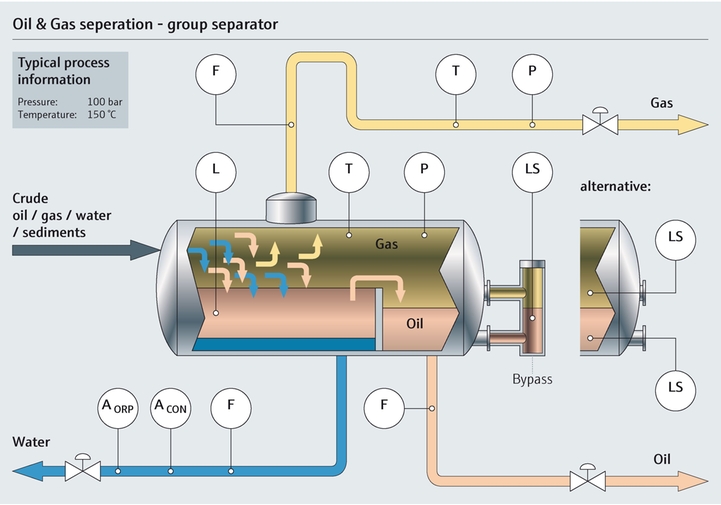

물과 침전물에서 탄화수소 액체를 분리하는 과정은 쉽지 않습니다. 분리 프로세스의 성능을 최적화하려면 온도, 압력, 레벨, 유량, 인터페이스 등 모든 핵심 파라미터에 대해 신뢰할 수 있는 정보가 필요합니다. 인터페이스의 측정은 노하우와 적용 기술에 따라 상대적으로 단순해지거나 극도로 복잡해질 수 있습니다.

핵심 정보

2,200

USD/ day

is the number of dollars spent in a day for demulsifiers

분리 프로세스의 효율성을 향상시키는 방법을 알아보십시오.

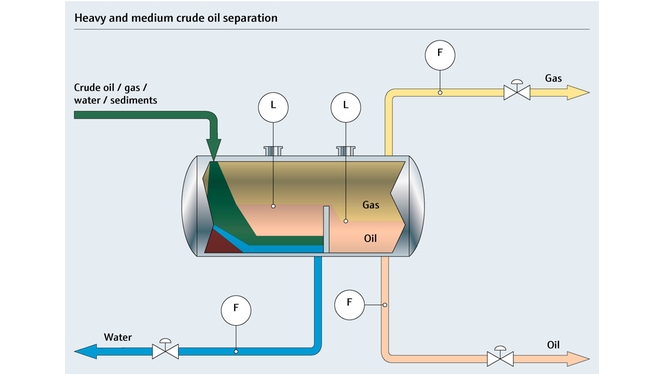

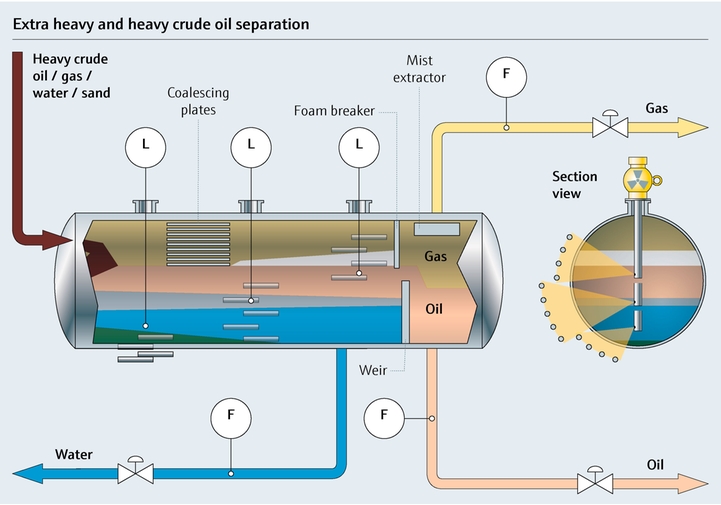

초중질유/중질유 분리 프로세스*

기존의 측정 기술은 초중질유/중질유 분리 프로세스에서 사용이 제한적입니다. 필요한 정보를 제공하지 못할 뿐만 아니라 분리 장치 내부에 설치해야 하기 때문에 쉽게 오염됩니다.

*중질유: > API 10 - 22,3 (> 920 kg/m³) 초중질유: < API 10 (> 1000 kg/m³)

분야별 전문성

엔드레스하우저의 감마 밀도 프로파일링 시스템은 탱크 외부에 설치되기 때문에 분리 프로세스를 방해하지 않을 뿐만 아니라 비용 절감 효과가 큽니다.

- 오염과 축적물로 인한 부정확한 측정 방지

- 분리 프로세스의 연속성 보장

- 운영 비용 감소

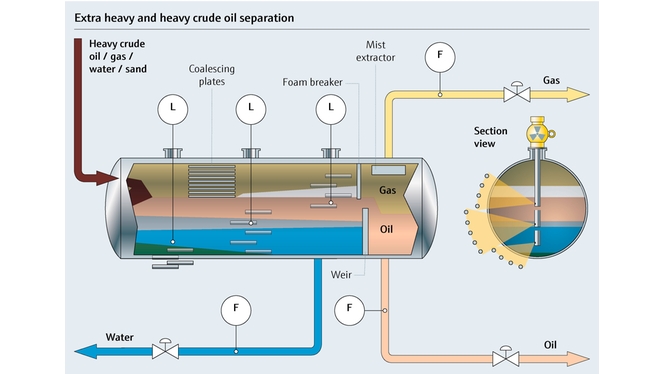

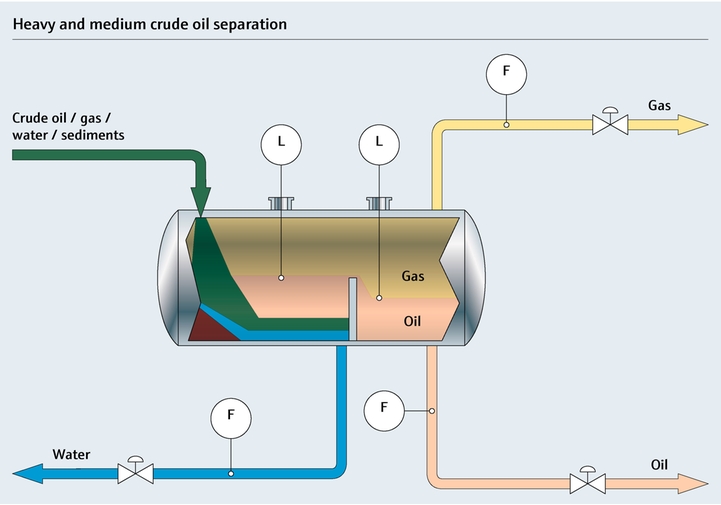

중질유 분리 프로세스*

중질유 분리의 경우 단일 계측 기기로 전체 레벨과 인터페이스를 모두 정확하게 측정하기가 불가능합니다. 에멀전층이 종종 존재할 뿐만 아니라 이러한 에멀전층이 5 cm (2 inch)를 넘을 경우 표준 가이드 레이다 기기로 인터페이스를 측정할 수 없습니다.

*중질유: API 31.1 - 22.3 (870 - 920 kg/m³)

분야별 전문성

엔드레스하우저는 이 문제를 해결하고 가동 중단을 최소화하기 위해 다중 파라미터 거아두 레이다 기술을 개발했습니다.

- 단일 계기를 사용해 중질유 분리 간소화

- 다중 파라미터 가이드 레이다 기술을 사용하여 에멀전 층을 통해 인터페이스 모니터링

- 프로세스 중단 최소화 및 운영 비용 감소

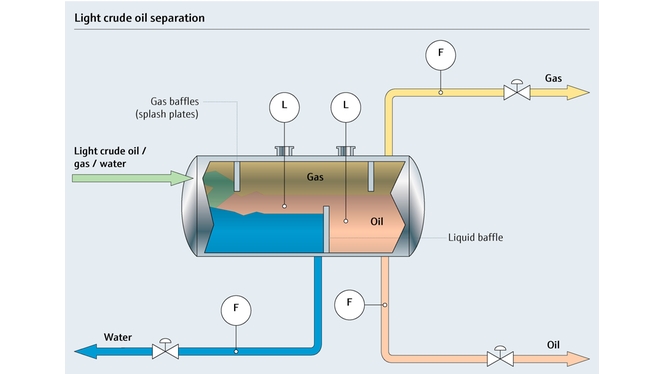

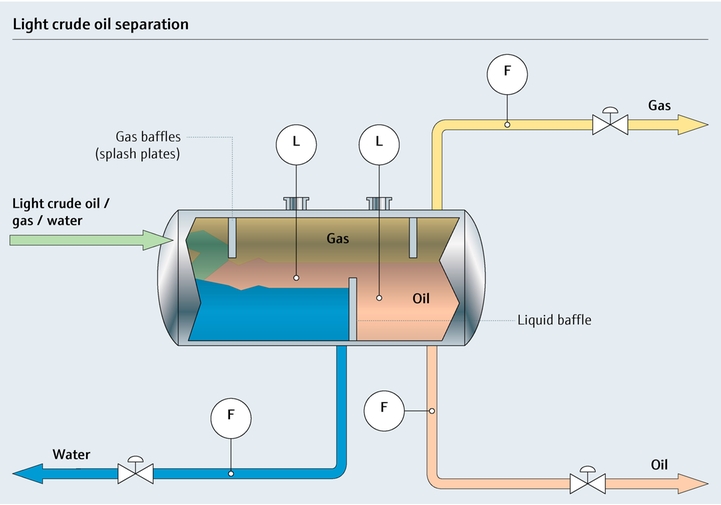

경질유 분리 프로세스*

오늘날 대부분의 수평 경질유 분리 장치에는 기계식 레벨 및 밀도 제어 기기가 장착되어 있습니다. 기계식 기기는 유지보수가 많이 필요할 뿐만 아니라 생산되는 정유에 맞춰 기기를 조정해야 합니다. 이 말은 생산되는 정유가에 변화가 있으면 측정 기기도 교체해야 한다는 뜻입니다.

*경질유: API 45 - 31.1 (< 870 kg/m³)

분야별 전문성

엔드레스하우저의 가이드 레이다는 이 문제를 해결하여 더욱 정확한 측정이 가능하며, 경질유 분리 프로세스를 최적화합니다.

- 인터페이스 측정의 새로운 기준인 Levelflex FMP55 사용

- 출력 전환 시 계기 조정으로 인한 가동 중지 방지

- 지속적인 운영 및 유지보수 비용 감소

장점

고객의 최대 관심사는 최대의 자원을 추출하는 것이고, 엔드레스하우저의 최대 관심사는 고객이 이러한 프로세스를 성공적으로 수행할 수 있도록 지원하는 것입니다. 엔드레스하우저의 프로세스 자동화 솔루션은 고객이 안전하고 효율적이며 깨끗한 프로세스를 운영하고 유지할 수 있도록 도와줍니다. 한 사람이 여러 시행착오를 거치며 쌓은 경험과 지식은 쉽게 대체할 수 있는 것이 아닙니다. 따라서 엔드레스하우저의 서비스 팀은 검사, 시운전, 엔지니어링 및 교정 서비스와 더불어 미래의 직원을 위한 교육 프로그램을 통해 개인 격차를 줄일 수 있도록 지원합니다.

핵심 정보

300+

전 세계에 설치된 방사선 인터페이스 측정 및 밀도 프로파일링 시스템의 수

핵심 정보

8,500L

연간 절약되는 분리제의 양(10%)

핵심 정보

5%

분리 장치 내부의 거품 발생 위험 감소 효과

엔드레스하우저의 지원 방식

정유, 물, 가스 및 모래의 분리를 효과적으로 제어하는 유일한 방법은 다양한 유체 형태를 측정하는 것입니다. 엔드레스하우저는 기름, 물, 모래의 분리 과정에서 효율적인 제어 및 관리가 가능한 솔루션을 제공합니다.

- 액체 및 침전물 층 위치 및 두께 식별, 유화제 및 소포제 주입 최적화

- 개방형 표준으로 제어 유연성 제공

- 프로파일링 솔루션의 구축을 위한 손쉬운 추가 장착

- 환경 표준 준수