자산 성과 관리(Asset Performance Management, APM) 는 정확하고 경쟁적인 제약 제조 분야에서 생산성, 규정 준수 및 가용성의 핵심입니다. 공정 플랜트는 지속적으로 발전하고 개선해야 하는 압력에 시달리고 있지만, 많은 플랜트가여전히 계획되지 않은 셧다운의 발생으로 예상치 못한 비용을 지불하고 있습니다. 당사의 프로세스 전문 지식과 혁신적인 기술을 통해 최적의 자산 관리 및 최고의 제약 생산 성능을 가능케 하는 예측적 유지 보수 전략을 경험해 보십시오.

핵심 정보

1.5%

ARC* 조사 기관에 따른 매출 수익에서 설비 자산 관리 불량으로 소진되는 비용 *https://www.scribd.com/document/327405557/Asset-Information-Management-Part-1-The-Case-for-Developing-an-AIM-Strategy

자산 관리 최적화와 플랜트 가용성 향상

데이터 기반 의사 결정

시간이 지나면서 프로세스 플랜트는 발전하고 장비는 교체되며 계기는 노후화됩니다. 따라서 설비의 자산 데이터를 수집하는 것은 여러 측정 포인트와 다양한 공급업체의 계기가 수반되는 노동 집약적인 프로세스가 될 수 있지만, 이러한 최신 정보 없이 유지보수 작업의 개선은 불가능합니다.

분야별 전문성

엔드레스하우저의 감사 팀은 모든 필요한 정보를 상세한 보고서에 수집하여 분석하는 설비 분석을 수행하고, 이를 기반으로 데이터 중심의 의사 결정을 내릴 수 있습니다.

- 자산 데이터 수집의 시간 및 비용 절감

- 중요 자산과 잠재적 개선에 관한 상세한 보고서를 기반으로 자산 관리 개선

- 노후화 설비 관리 최적화 및 계기 표준화 간소화

원격 실시간 모니터링 및 정보

계기의 오류 코드를 진단하고 해결하려면 때때로 현장 작업이 필요한데, 이는 비용 상승과 위험 증가를 초래할 수 있습니다.

분야별 전문성

엔드레스하우저의 Netilion IIoT 생태계는 계기 데이터를 실행 가능한 정보(actionable information)로 전환하는 앱과 알고리즘으로 구성됩니다. 간편한 스마트폰 앱에서 설치된 계기를 모니터링하고 오류 코드를 진단하여 원격으로 문제를 해결할 수 있습니다. 이제 디지털 플랜트는 꿈이 아니라 현실입니다.

- Scanner 앱으로 물리적 자산의 디지털 트윈을 60초 안에 생성

- Netilion Analytics 앱에서 제공하는 라이브 설비 개요를 통한 분석 수행

- Netilion Health 앱을 통해 오류 코드를 확인하고 필요한 조치를 명확하게 전달

예측 가능한 유지보수

대부분의 계측기기 오류는 예측할 수 없으며, 오류가 발생하는즉시 가동이 중지되어 많은 비용이 요구됩니다.

분야별 전문성

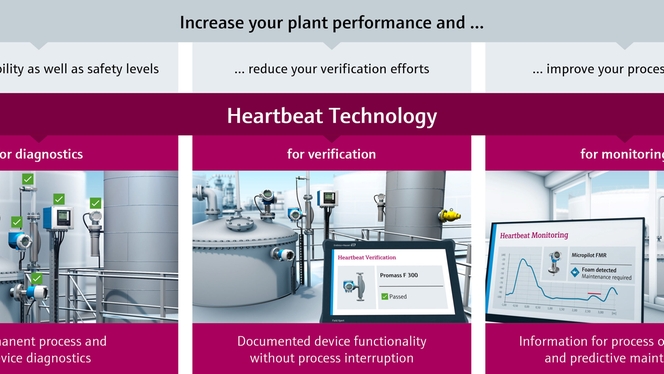

하트비트 기술(Heartbeat Technology)을 이용하면 계기 상태를 영구적으로 모니터링하는 자가 진단 기능을 계기에 내장할 수 있습니다. 이러한 분석을 바탕으로 트렌드를 파악하거나, 오류가 발생하기 전에 조치를 취하거나, 언제 교정이 필요한지 예측할 수 있습니다.

- 프로세스 중단 없이 최대 98%의 영구적인 프로세스 및 계기 진단 범위 보장

- 명확하고 표준화된 진단 메시지를 통한 유지보수 간소화

- 예기치 않은 계기 고장으로 인한 가동 중단 최소화

데이터 보안

생명과학 산업에서는 데이터 무결성과 데이터 보안이 매우 중요합니다.

분야별 전문성

엔드레스하우저의 IIoT 솔루션은 최대의 데이터 보안을 보장하는 것으로 인증을 받았습니다. 종단 장치에서 클라우드의 고객 데이터에 이르기까지 엔드레스하우저는 최첨단 안전 메커니즘을 이용합니다.

- 긴 키 코드를 사용하는 암호화 방법(HTTPS / TLS 및 SHA-256)

- 인증된 데이터 센터와 협력(예: ISO 27001)

- 4성 등급의 EuroCloud에서 허가한 독립 기관의 인증

장점

엔드레스하우저는 고객이 자산 성과 관리를 최적화하고 자산 신뢰성을 극대화하도록 지원하는 전문성과 솔루션을 갖추고 있습니다. 스마트 계기, 전문가 서비스 및 클라우드 기반 유지보수 솔루션을 통해 안전과 규정 준수를 저해하지 않으면서 예측 유지보수와 디지털화를 향해 한 걸음 더 나아갈 수 있습니다.

핵심 정보

80%

엔드레스하우저 고객사 중 한 곳에서 IBA를 기반으로 온도 계기를 표준화한 후 감소한 변동성

핵심 정보

최대 30%

플랜트에 설치된 자산 중 노후화된 자산의 비율

엔드레스하우저의 지원 방식

엔드레스하우저는 고객이 자산 관련 지식을 높이고 효과적으로 계기 유지보수를 수행하게 함으로써 고객의 자산 성과 관리를 최적화합니다.

- 현장에 설치된 계기로부터 발생하는 데이터를 바탕으로 한 종합적인 계기 상태 파악

- 최신 자산 정보를 위한 스마트 센서 및 클라우드 IIoT 솔루션

- 자산의 예측적 유지 보수를 위한 자체적인 자가 진단 기능

- 가동 중지 시간 감소 및 예비 부품 관리 개선을 위한 예측적 유지보수 전략

- 유지보수 작업을 위한 실시간 모니터링