사양 정보

-

Max. measurement error

3 % o.r.

4 % o.r.

5 % o.f.s.

(depending on chosen option of ordering feature "Calibration flow") -

Measuring range

20 to 720 000 kg/h (45 to 1 587 600 lb/h)

20 to 1 080 000 kg/h (45 to 2 381 400 lb/h)

(for air, depending on chosen option of ordering feature "Calibration flow") -

Medium temperature range

–40 to +100 °C (–40 to +212 °F)

-

Max. process pressure

20 bar g (290 psi g)

-

Wetted materials

Transducer: 1.4404 (316L)

Insertion tube: 1.4404 (316L); 1.4435 (316L)

Connection:

Compression fitting: 1.4404 (316L)

Sealing ring: EPDM; HNBR; 1.4401 (316)

Clamping ring: PEEK 450G

적용 분야

t-mass B 150 삽입형 버전은 대형 배관이나 직사각형 통풍 덕트에 적합하고, 설비 기체, 특히 압축 공기의 비용 효율적인 측정을 위해 설계되었습니다. 또한 보조 계량 어플리케이션을 위한 트렌딩 계기이고, 견고하고 컴팩트한 알루미늄 하우징에 4선식 기술이 탑재되었습니다. 디스플레이에 고객별 설정을 저장할 수 있고 디스플레이를 통해 한 계기에서 다른 계기로 전송할 수 있습니다.

넓은 유량 범위와 직접 질량 유량 측정이 특징인 측정 원리

순환 배관 또는 직사각형 덕트의 공기, 질소, 이산화탄소 및 아르곤에 적합

계기 특징

공칭 직경 DN 80 ~ 1500(3 ~ 60")을 위한 삽입형 버전

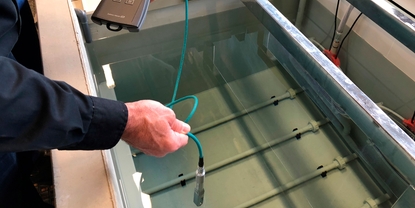

프로세스 중단 없이 센서 설치 및 제거 가능

간편한 설치

DC 24 V 전원 공급 장치를 사용하는 컴팩트 버전 계기

4-20 mA HART, 펄스/주파수/스위치 출력

컴팩트하고 견고한 트랜스미터

장점

순환 배관 또는 직사각형 덕트의 공기, 질소, 이산화탄소 및 아르곤에 적합

최적의 프로세스 모니터링 – 낮은 압력과 느린 유량 속도에서도 손쉽게 측정

비용 효율적인 측정 – 간편한 설치, 압력 손실이 거의 없고 유지보수가 불필요

신뢰할 수 있는 유량 트렌딩 – 다변수 측정

빠르고 효율적인 시운전 – 안내식 작동 메뉴

높은 플랜트 가용성 – 자가 진단 및 오류 모니터링

정비를 위한 자동 데이터 복원

동영상

| FLEX 선택 | 기술적 우수성 | 단순성 |

|---|---|---|

Fundamental 선택 기본적인 측정 요구사항 충족 |

기술적 우수성

|

단순성

|

Lean 선택 핵심 프로세스를 손쉽게 처리 |

기술적 우수성

|

단순성

|

Extended 선택 혁신적인 기술로 프로세스 최적화 |

기술적 우수성

|

단순성

|

Xpert 선택 가장 까다로운 어플리케이션 요구사항 충족 |

기술적 우수성

|

단순성

구성에 따라 다름 |

Loading alternative products

Loading alternative products

기존 제품

-

-

사용 설명서(BA)

Proline t-mass B 150 HART Operating Instructions

영어 버전 - 11/2012

Thermal Mass Flow Measuring System

EN KO 09/11/201217/04/2012언어:

영어

버전:

09/11/2012

파일 크기:

3 MB

파일 이름:

BA01043DEN_0212.pdf

-

-

-

기술 정보(TI)

Proline t-mass B 150 Technical Information

영어 버전 - 05/2012

Thermal Mass Flow Measuring System

EN KO 11/05/201217/04/2012언어:

영어

버전:

11/05/2012

파일 크기:

1 MB

파일 이름:

TI01020DEN_0212.pdf

-

-

-

기술 정보(TI)

Proline t-mass B 150 Technical Information

Thermal Mass Flow Measuring System

EN KO 11/05/201217/04/2012언어:

영어

버전:

11/05/2012

파일 크기:

1 MB

파일 이름:

TI01020DEN_0212.pdf

-

-

-

사용 설명서(BA)

Proline t-mass B 150 HART Operating Instructions

Thermal Mass Flow Measuring System

EN KO 09/11/201217/04/2012언어:

영어

버전:

09/11/2012

파일 크기:

3 MB

파일 이름:

BA01043DEN_0212.pdf

-

-

-

계기 파라미터(GP)

Proline t-mass A, B 150 HART Description of Device Parameters

Thermal Mass Flowmeter

EN KO 04/04/2016언어:

영어

버전:

04/04/2016

파일 크기:

1.5 MB

파일 이름:

GP01031DEN_0115.pdf

-

-

-

요약 지침서(KA)

Proline t-mass B 150 Brief Operating Instructions

Thermal Mass Flow Measuring System

EN KO 17/04/2012언어:

영어

버전:

17/04/2012

파일 크기:

1.4 MB

파일 이름:

KA01104DEN_0112.pdf

-

-

-

설치 설명서(EA)

Replacing the display module Installation Instructions

Promag 200, Promass 200, Prosonic Flow 200, Prowirl 200, t-mass 150,

Levelflex FMP5x, Micropilot FMR5x, Micropilot FMR6x, Remote dis

play FHX50 -

-

-

설치 설명서(EA)

Replacing sensor A+B Installation Instructions

t-mass A, B 150

EN KO 01/10/201827/03/201524/04/2012언어:

영어

버전:

01/10/2018

파일 크기:

435.9 KB

파일 이름:

EA00112DA2_0318.pdf

-

-

-

설치 설명서(EA)

Safety Instructions for Spare Parts Installation Instructions

Flowmeter

EN KO 01/03/201828/11/201325/04/2013언어:

영어

버전:

01/03/2018

파일 크기:

139.5 KB

파일 이름:

EA01051DA2_0318.pdf

-

-

-

설치 설명서(EA)

Activating application packages

Promag 100, 200, 400, Promass 100, 200, Prosonic Flow 100, 200, Prowirl

200, t-mass 150EN KO 03/03/202015/02/2019언어:

영어

버전:

03/03/2020

파일 크기:

406.9 KB

파일 이름:

EA01249DA2_0220.pdf

-

-

-

설치 설명서(EA)

Hot tap

t-mass B 150

EN KO 01/04/202201/10/201824/04/2012언어:

영어

버전:

01/04/2022

파일 크기:

1.4 MB

파일 이름:

EA00109DA2_0322-00.pdf

-

-

-

설치 설명서(EA)

EA Cold tap, atmospheric pressure

t-mass B, T 150, I 300, 500-digital

EN KO 15/10/202431/07/202001/10/201804/10/2016언어:

영어

버전:

15/10/2024

파일 크기:

539.9 KB

파일 이름:

EA01136DA2_0424-00.pdf

-

%20-%20CS01637X.jpg)