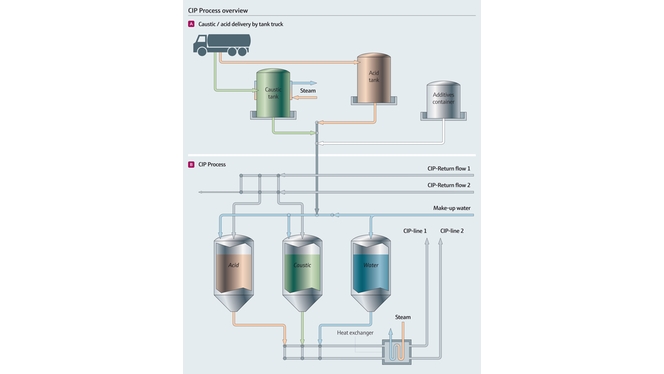

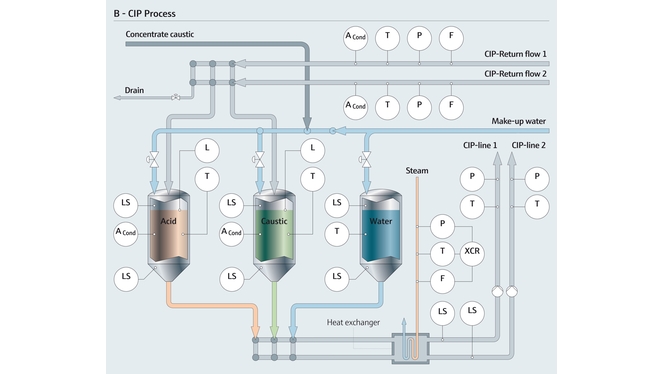

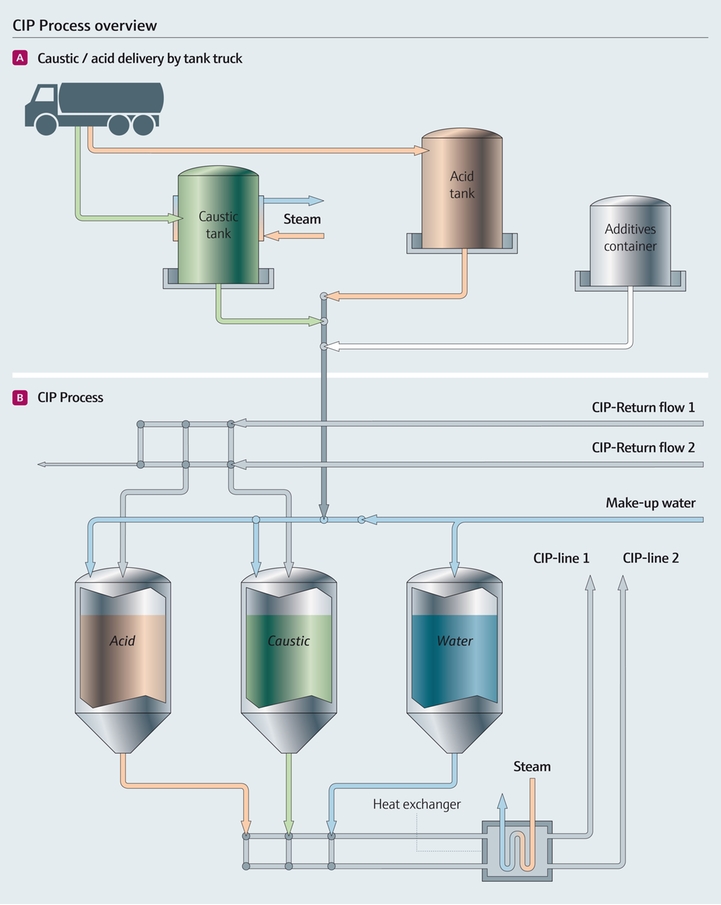

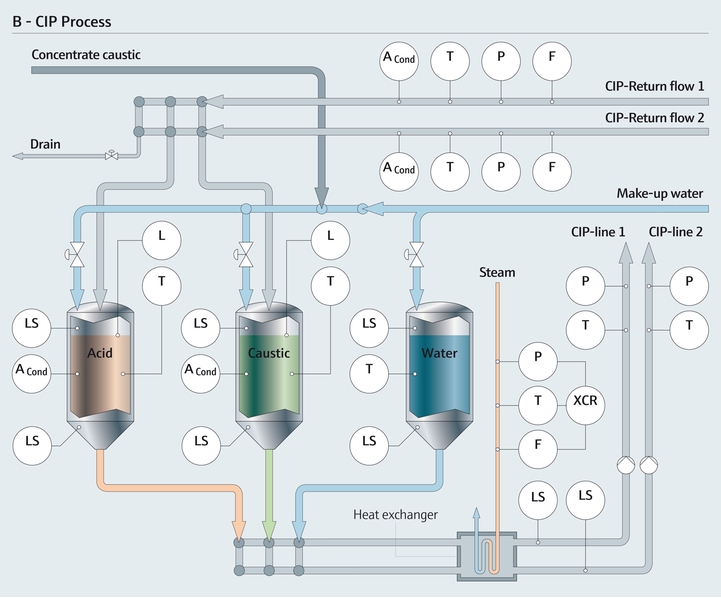

원자재와 에너지의 비용이 상승하면서 식음료 플랜트 내의 자산 이용이 더욱 중요해지고 있습니다. 많은 식품 가공업체들은 여전히 시간 측정 기반 프로세스와 수동 검증에 의존하여 자동화 수준이 낮은 CIP(Clean in Place) 시스템을 운영하고 있습니다. 인라인 계측 기기를 설치하면 실시간 모니터링과 제어가 가능해 세척 시간, 에너지 및 세척제 사용을 줄이고 완전한 추적성을 보장할 수 있습니다.

핵심 정보

30%

savings on cleaning agent costs

by ensuring correct detergent strength and phase separation with Endress+Hauser's conductivity and optical measurements.

엔드레스하우저가 제공하는 가치

CIP 프로세스에서 제품 손실과 에너지 비용을 줄이는 방법을 자세히 알아 보십시오!

정확한 농도 측정

CIP 시스템의 성능을 최적화하려면 루프와 보충수 탱크의 세척제 농도를 알아야 합니다.

분야별 전문성

전도도 측정은 유지보수 및 교정 요건이 가장 낮고, 전도도 측정을 통해서 에너지, 화학물질 및 용수 사용을 줄일 수 있습니다. 엔드레스하우저는 입문용 소형 시스템에서 Ethernet 기능이 통합된 멀티채널 시스템에 이르기까지 CIP 서비스에 특화된 다양한 전도도 센서와 트랜스미터 옵션을 제공합니다.

- 어플리케이션에 최적화된 전도도 센서와 트랜스미터를 통해 농도 측정을 최적화 해보십시오.

효율적인 위상 분리

라인의 상황을 정확히 파악하고 추측에 의존한 상황 파악을 최소화해 보십시오. 전환 센서는 CIP 사이클의 각 위상이 언제 끝나고 다음 위상이 언제 시작하는지 결정합니다.

분야별 전문성

전도도, 광학 탁도 또는 pH 센서는 헹굼 후 제품이 남아 있지 않은 경우에만 제품이나 헹굼수를 CIP 시스템을 시작하는 라인에 넣는 데 사용됩니다. 제품 및 물 손실을 줄이고 시간을 절약하려면 빠른 응답 시간이 매우 중요합니다.

- 엔드레스하우저의 수질 분석계 포트폴리오를 통해 가장 최적화된 계기를 찾아내고, 효율적인 위상 분리를 경험해보십시오.

신뢰할 수 있는 레벨 측정

안정적인 공급을 위해서는 CIP 세척제의 재고를 모니터링해야 합니다.

분야별 전문성

가장 일반적인 세척제 보관 방법은 초음파, 접촉식 레이다, 또는 비접촉식 레이다입니다. 일반적으로 보충수, 헹굼 및 회수 탱크에는 수두압 또는 정전용량 센서를 사용하고, 탱크 크기와 개인적 선호에 따라 센서를 선택합니다. 시스템 안전은 저/고 레벨 경보와 빈 파이프 검출 기능을 통해 보장되고(펌프 보호), 가장 일반적으로 진동 포크식 전도성/정전용량 센서를 사용합니다.

- 광범위한 측정 원리 및 관련 제품 포트폴리오를 통해 고객님의 어플리케이션에 가장 최적화된 레벨계를 확인해 보세요.

내구성이 우수한 유량 측정 계기

유량 측정은 효율적인 CIP 시스템을 위해 반드시 필요하고, 강한 난류를 통해 필요한 세정 효과에 도달할 수 있습니다.

분야별 전문성

Promag H 제품군은 승온에서, 그리고 난류로 인해 정상 수준보다 높은 진동에서 강한 화학물질을 처리하도록 설계되었습니다. 엔드레스하우저는 유량, 온도, 전도도 측정 값을 모두 제공하는 유량계를 제안 드리며, CIP 서비스 관련 축적된 노하우를 바탕으로 효율적인 솔루션을 제공합니다.

- 유량값뿐만 아니라, 전도도 및 온도 측정이 가능한 전자유량계를 확인해 보십시오.

온도 측정 시 비용 절감

CIP 프로세스 내의 온도는 여러 위치에서 확인할 수 있고 세척 효율과 에너지 소비 간의 균형을 유지하기 위해 정밀하게 제어됩니다. 중요 제어 개소로 간주되는 온도는 빈번한 교정 검사가 필요한데, 엔드레스하우저의 QuickNeck을 통해 간단히 해결할 수 있습니다.

분야별 전문성

iTHERM QuickNeck-엔드레스하우저의 온도 센서는 특허 받은 기술로 캘리브레이션이 용이하도록 설계되었습니다. 드라이버와 같은 도구 없이 손으로 회전시키는 것만으로 써모웰과 센서부를 완전히 분리 가능합니다.

- QuickNeck 기술이 적용된 온도 센서 iTHERM TM411을 통해 사전에 고장을 예방하고 유지보수에 소요되는 시간을 절약할 수 있습니다.

효율적인 세척을 보장하는 빌드업 모니터링

효율적인 세척은 세척 환경의 온도, 세제 농도 및 유속/전단력을 기반으로 합니다. 그러나 파이프가 언제나 직선 형태로 되어 있지 않을 뿐만 아니라 스프레이 볼의 도달 범위가 항상 이상적이지는 않기 때문에 세척을 진행하는 데 어려움이 수반될 수 있습니다. 프로세스 전체에 걸친 전반적인 세척 효율도를 보장하기 위해서는 세척이 이루어지는 장소에 대한 지속적인 모니터링이 필요합니다.

분야별 전문성

빌드업 측정을 위한 컴팩트한 전도도 센서 Liquitrend QMW43은 빌드업 두께 및 전도도를 동시에 측정할 수 있습니다. 저온 살균 공정의 홀딩 튜브에 설치되어 빌드업의 형성 여부를 지속적으로 모니터링함으로써 세척 과정이 필요한지 또는 제품 품질에 영향을 미치지 않으면서 생산 시간을 계속 연장할 수 있는지 여부를 결정하는 데 도움이 됩니다.

장점

엔드레스하우저는 고객과 함께 CIP 효율성의 개선에서 탁월한 성과를 달성해 왔으며, 업계와 어플리케이션에 관한 전문성과 광범위한 제품 포트폴리오를 기반으로 고객의 성공을 보장합니다. 엔드레스하우저의 목표는 모든 측면에서 신뢰할 수 있는 파트너가 되는 것입니다.

핵심 정보

25-30%

각 CIP 사이클의 시간 절약 효과

핵심 정보

30%

위상 분리에서 광학 기술의 사용으로 인한 화학물질 사용 감소

핵심 정보

>100

엔드레스하우저의 어플리케이션 및 업계 전문성으부터 혜택을 누린 국가 수

엔드레스하우저의 지원 방식

엔드레스하우저는 까다로운 CIP 어플리케이션에서 고객이 직면한 과제를 이해하고, 이러한 과제의 해결을 위한 완전한 위생 측정 솔루션 제품군을 제공합니다. 엔드레스하우저의 입증된 유량, 레벨, 압력 및 온도 측정 기기와 분석 기기는 최고의 품질 표준을 준수하고 모든 식음료 요건과 규정을 충족하도록 설계되었습니다. 엔드레스하우저가 제공하는 가치는 다음과 같습니다.

- 3-A, FDA 및 EHEDG의 완벽한 준수

- 에너지 비용 및 가동 중단의 감소

- 산업별로 최적화되어 내구성이 우수하고 신뢰성이 높은 계측 기기

- 모든 제어 플랫폼과 완벽히 통합

- 모든 어플리케이션에서 정확한 측정을 보장하는 혁신적인 자가 진단 기능