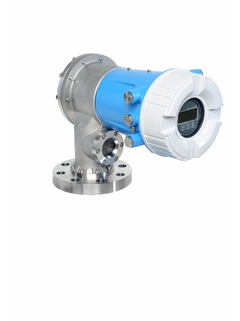

사양 정보

-

Accuracy

up to 0.4 mm

-

Process temperature

-200°C...200°C

(-328°F...392°F) -

Process pressure / max. overpressure limit

up to 25 bar (363 psi) abs

-

Max. measurement distance

47 m (154 ft)

-

Main wetted parts

316L, AlloyC276, PTFE

적용 분야

The intelligent tank gauge Proservo NMS81 is designed for high accuracy liquid level measurement in custody transfer and inventory control applications with NMi- and PTB-approvals. It meets the relevant requirements according to OIML R85 and API 3.1B. It fulfills the exact demands of tank inventory management and loss control and is optimized in regards of total cost saving and safe operation.

For high accuracy custody transfer measurement in crude oil, gasoline, diesel, petrochemicals and chemicals.

Process connections: Flanges

Temperature: -200 to +200°C (-328 to +392°F)

Pressure: 0 to +25bar (0 to +362psi)

Maximum measuring range: 47m (154ft)

Accuracy: ±0.4mm (±0.02")

International explosion protection and custody transfer certificates, overfill prevention WHG, SIL

장점

-

Hardware and software developed according to IEC 61508 up to SIL3 (in homogeneous redundancy) for high level of safety

-

Maximum reliability through accuracy up to ±0.4mm (± 0.02")

-

Developed according to international metrology recommendations such as OIML R85 and API MPMS

-

Local and country-specific certifications like NMi or PTB for custody transfer applications

-

Superior corrosion resistance with 316L materials in the process compatible with sour applications such as crude oil

-

Measurement of interfaces between up to three liquid layers, tank bottom, spot, and profile densities

-

Best fit for LNG/LPG applications without influence of dc value or Boil Off Gas

동영상

| FLEX 선택 | 기술적 우수성 | 단순성 |

|---|---|---|

Fundamental 선택 기본적인 측정 요구사항 충족 |

기술적 우수성

|

단순성

|

Lean 선택 핵심 프로세스를 손쉽게 처리 |

기술적 우수성

|

단순성

|

Extended 선택 혁신적인 기술로 프로세스 최적화 |

기술적 우수성

|

단순성

|

Xpert 선택 가장 까다로운 어플리케이션 요구사항 충족 |

기술적 우수성

|

단순성

구성에 따라 다름 |

Loading alternative products

Loading alternative products

기존 제품

-

-

계기 파라미터(GP)

Proservo NMS81

Tank Gauging

EN KO 17/02/202320/07/201829/06/201701/03/2016언어:

영어

버전:

17/02/2023

파일 크기:

4.5 MB

파일 이름:

GP01077GEN_0423-00.pdf

-

-

-

설치 설명서(EA)

Cover, cover clamp, O-ring Installation Instructions

Microwave Level Measurement

EN KO 14/12/201830/11/2016언어:

영어

버전:

14/12/2018

파일 크기:

900.5 KB

파일 이름:

EA01176GA2_0218.pdf

-

-

-

설치 설명서(EA)

SD card with holder Installation Instructions

Micropilot NMR8x; ProservoNMS8x; Tankside Monitor NRF81

EN KO 30/09/201730/11/2016언어:

영어

버전:

30/09/2017

파일 크기:

1 MB

파일 이름:

EA01184GA2_0217.pdf

-

-

-

설치 설명서(EA)

Sensor assembly Installation Instructions

Tank Gauging

EN KO 30/10/201719/10/2017언어:

영어

버전:

30/10/2017

파일 크기:

3.5 MB

파일 이름:

EA01225GF3_0317.pdf

-

-

-

설치 설명서(EA)

Housing filter Installation Instructions

Micropilot, Proservo, Tankside Monitor

EN KO 28/02/201830/11/2016언어:

영어

버전:

28/02/2018

파일 크기:

404 KB

파일 이름:

EA01183GA2_0218.pdf

-

-

-

설치 설명서(EA)

Displacer unit, Servo Installation Instructions

Proservo NMS8x

EN KO 24/10/2017언어:

영어

버전:

24/10/2017

파일 크기:

1.9 MB

파일 이름:

EA01234GF3_0117.pdf

-

-

-

설치 설명서(EA)

O-ring, Servo Installation Instructions

Proservo NMS8x

EN KO 24/10/2017언어:

영어

버전:

24/10/2017

파일 크기:

3.2 MB

파일 이름:

EA01235GF3_0117.pdf

-

-

-

설치 설명서(EA)

Wire drum, measuring wire unit, Servo

Proservo NMS8x

EN KO 23/06/2022언어:

영어

버전:

23/06/2022

파일 크기:

2.1 MB

파일 이름:

EA01434GEN_0122-00.pdf

-

-

-

설치 설명서(EA)

Display set, display holder Installation Instructions

Micropilot NMR8x; Proservo NMS8x; Tankside Monitor NRF81

EN KO 30/11/2016언어:

영어

버전:

30/11/2016

파일 크기:

1.1 MB

파일 이름:

EA01185GA2_0116.pdf

-

-

-

설치 설명서(EA)

Terminal set Installation Instructions

Micropilot NMR8x; Proservo NMS8x;Tankside Monitor NRF81

EN KO 30/11/2016언어:

영어

버전:

30/11/2016

파일 크기:

1 MB

파일 이름:

EA01186GA2_0116.pdf

-

-

-

설치 설명서(EA)

Wire drum, measuring wire unit, Servo Installation Instructions

ProservoNMS8x

EN KO 01/01/2018언어:

영어

버전:

01/01/2018

파일 크기:

2.7 MB

파일 이름:

EA01236GF3_0118.pdf

-

-

-

설치 설명서(EA)

I/O module, electronics mainboard, frontplane assembly, labelled Installation Instructions

Micropilot NMR8x; Proservo NMS8x; Tankside Monitor NRF81

EN KO 31/08/201831/05/201730/11/2016언어:

영어

버전:

31/08/2018

파일 크기:

1.5 MB

파일 이름:

EA01174GA2_0318.pdf

-

-

-

설치 설명서(EA)

Sensor module, Servo Installation Instructions

Tank Gauging

EN KO 30/10/201726/10/2017언어:

영어

버전:

30/10/2017

파일 크기:

2.9 MB

파일 이름:

EA01231GF3_0317.pdf

-

-

-

설치 설명서(EA)

Electronic box Installation Instructions

Micropilot NMR8x; Proservo NMS8x; Tankside Monitor NRF81

EN KO 02/07/201830/11/2016언어:

영어

버전:

02/07/2018

파일 크기:

1.3 MB

파일 이름:

EA01177GA2_0218.pdf

-

-

-

설치 설명서(EA)

Bearing, Servo Installation Instructions

Proservo NMS8x

EN KO 24/10/2017언어:

영어

버전:

24/10/2017

파일 크기:

3.4 MB

파일 이름:

EA01233GF3_0117.pdf

-

-

-

Ex 안전 지침서(XA)

XA Proservo NMS80, NMS81, NMS83

Ex db[ia Ga] IIC T6...T1 Ga/Gb

EN KO 01/09/202322/01/202215/05/2021언어:

영어

버전:

01/09/2023

파일 크기:

831.2 KB

파일 이름:

XA02544GEN_0323-00.pdf

-

-

-

Ex 안전 지침서(XA)

Safety Instruction Proservo NMS8x series

Safety instructions for Electrical Apparatus Certified for Use in

Explosion-hazardous Areas언어:

일본어

버전:

08/11/2016

파일 크기:

1.8 MB

파일 이름:

XA01600G-A08JA01.16_NMS8_TIIS.pdf

-